Rotech Celebrates 20 years of Supporting a Leading West Midlands Bespoke Fittings and Steel Pipes Manufacturer.

Rotech is celebrating 20 years of collaboration with a leading West Midlands based fittings and pipes manufacturer.

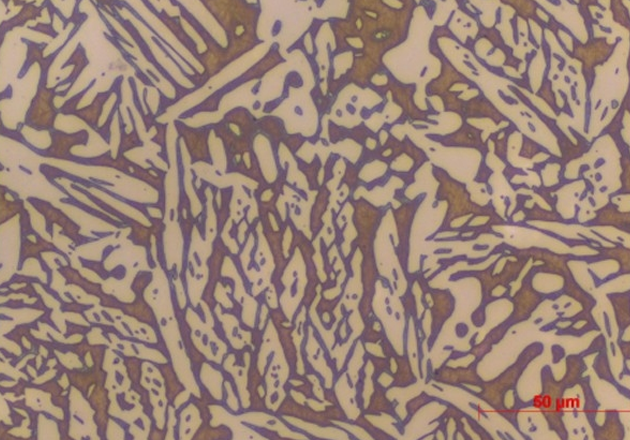

Over the course of the past two decades, Rotech has assisted the customer by providing on-site independent UKAS accredited testing, and providing quality assurance of welded duplex austenitic/ferritic stainless-steel plates and pipes to ASTM standards.

The fittings customer is a leading manufacturer of large diameter fittings and bespoke lengths of steels pipes.

Scroll down for more information.