Mechanical Testing

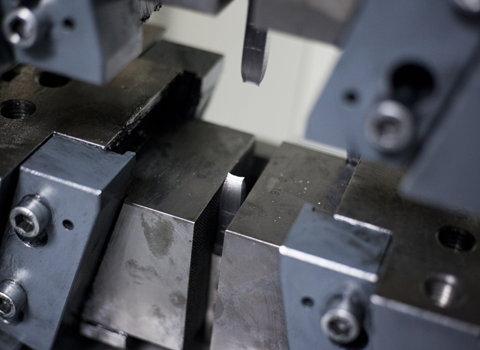

Mechanical testing services are a long-established mainstay of the business, and Rotech has a large, well-equipped sample preparation workshop and test house facility.

Mechanical testing is performed to determine whether a material is suitable for its final application, for quality control or in research and development to predict how a material will react under other types of forces. This is achieved by measuring properties such as Young’s Modulus, tensile strength, yield strength, elongation, reduction in area, hardness and impact resistance.