Hardness Testing

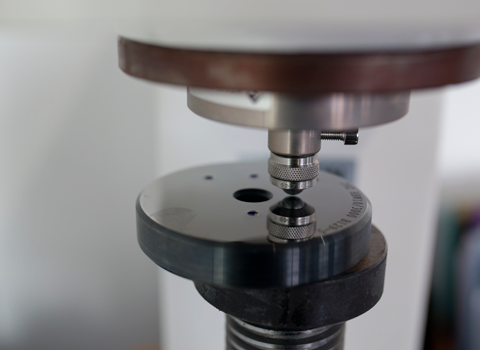

Hardness testing is a non-destructive test method that involves applying a constant load via a rounded or pointed object, under controlled conditions, to create an indentation in a metal surface. This is then measured to determine the hardness of the material.

Hardness testing goes hand-in-hand with tensile testing, as it is a good indicator of mechanical properties within materials. It indicated a material’s ability to resist indentation and, as such, gives an indication of strength, wear resistance and toughness.

The process involves the application of a constant load on a rounded or pointed indenter to create and indentation in the material surface. The depth of penetration is then measured to provide an indication of hardness. Although it can be done as a stand-alone test, it is usually carried out in conjunction with other mechanical tests as an overall assessment of material properties.

Hardness affects a wide range of physical characteristics, such as how much the metal will wear, scratch, or withstand stress.

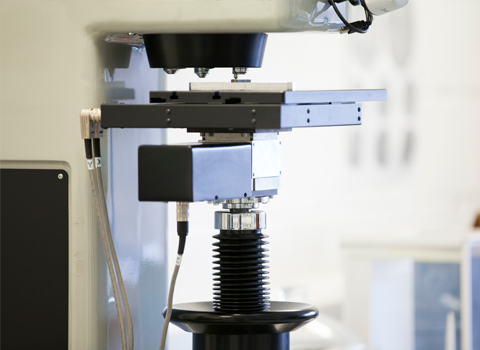

There are several methods of hardness tests available, each with their own standards and benefits., but choosing the right hardness test is usually governed by the size and geometry of the sample, the area to be tested and ease of application.

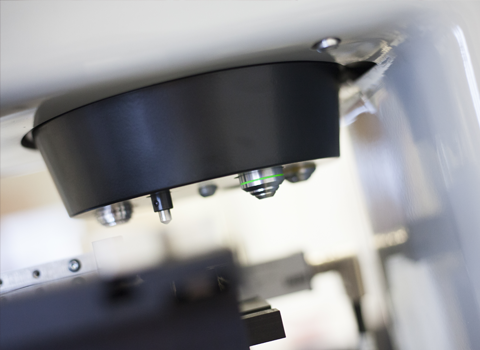

Our mechanical department specialises in Rockwell, Brinell, and Vickers hardness tests. Our metallurgical department also provides microhardness testing, including Knoop Testing and Vickers Microhardness.