(-196°C and -120°C to ambient) BS EN ISO 148-1: ASTM A370, ASTM E23.)

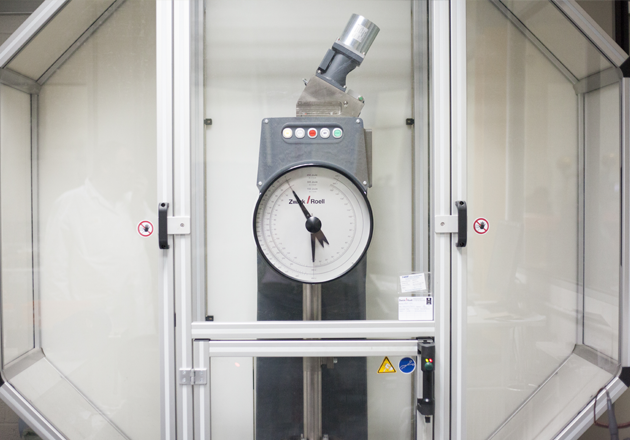

Charpy (V-notch) testing is a high strain-rate test that involves striking a Standardised notched sample. This is held by a set of support anvils and located using verified tongs, in a central horizontal position to receive a controlled weight pendulum swung from a set height.

The Charpy testing method helps measure the amount of energy absorbed by the specimen during fracture to measure the materials toughness. Charpy impact testing is commonly used to assess metals that are susceptible to sudden shock like those used in machinery and equipment in the construction and automotive industries.

The test is carried out to determine the specified mechanical properties material such as steel, stainless steel and related alloy products for their evaluation of conformance to help overcome any production issues.