Metallography & Metal Testing

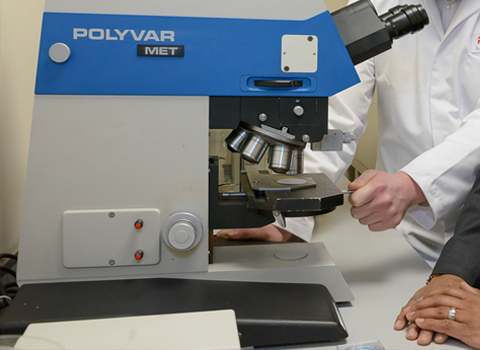

Metallography is the study of materials' microstructure. This procedure helps to establish if the material has been processed correctly. It’s also a critical step in determining product reliability and understanding why a material failed.

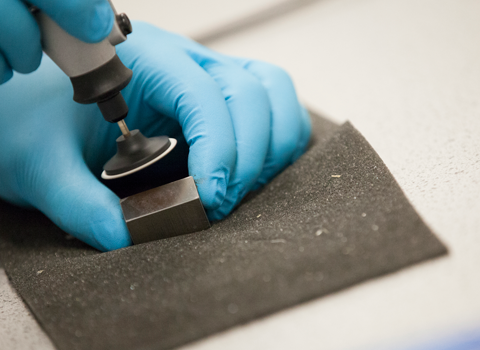

The basic steps for correct metallographic specimen preparation include grinding and polishing, and etching to reveal the structure of the specimen. Metallographic and materialographic specimen preparation seeks to find the true structure of the material.

Metal testing plays an important role in ensuring the quality, safety and reliability of metals used in various industries and applications. The process can increase the longevity of metals used in infrastructure or machinery by making sure materials have the right strength and corrosion resistance. It also helps businesses comply with strict regulations, ensuring materials meet specific requirements and safety standards.

Our team of qualified and experienced metallurgists provide a wide range of metal testing activities, including Cleanliness Testing*, Corrosion Testing, Failure Investigations and SEM & EDX Analysis. Find out more about our services below.

The activities identified with * are not UKAS accredited.